PFASER gives our clients an efficient method to eliminate persistent contaminants in water. Its adaptability makes it a powerful tool for industries and communities facing serious PFAS contamination in water.

Pro aqua’s patented boron-doped diamond electrodes are the new gold standard for wastewater treatment. Together with WSP, we deliver a reliable, long-lasting solution that protects public health and meets strict regulatory demands.

What are PFAS, and why are they called “forever chemicals”?

PFAS (per- and polyfluoroalkyl substances) are synthetic chemicals known for their persistence in the environment and the human body, hence the nickname “forever chemicals’’.

PFAS are found in various products, including non-stick cookware, water-resistant fabrics, firefighting foams, and even in some food packaging. They can also contaminate water sources near industrial sites and landfills.

Exposure to certain PFAS has been linked to health issues such as cancer, liver damage, thyroid disease, and developmental effects in infants.

PFAS can enter water supplies through industrial discharge, firefighting foam runoff, and leachate from landfills containing PFAS-laden products.

Certain home filtration systems, such as those using activated carbon or reverse osmosis, can reduce PFAS levels in drinking water. However, these methods may not completely eliminate all PFAS compounds.

On-site destruction of PFAS, using technologies like electro-oxidation, can prevent the risks associated with transporting hazardous waste and reduce potential environmental contamination.

Costs vary depending on the technology, scale, and specific application. While some methods may have higher initial investments, they offer long-term savings by effectively eliminating PFAS and reducing liability.

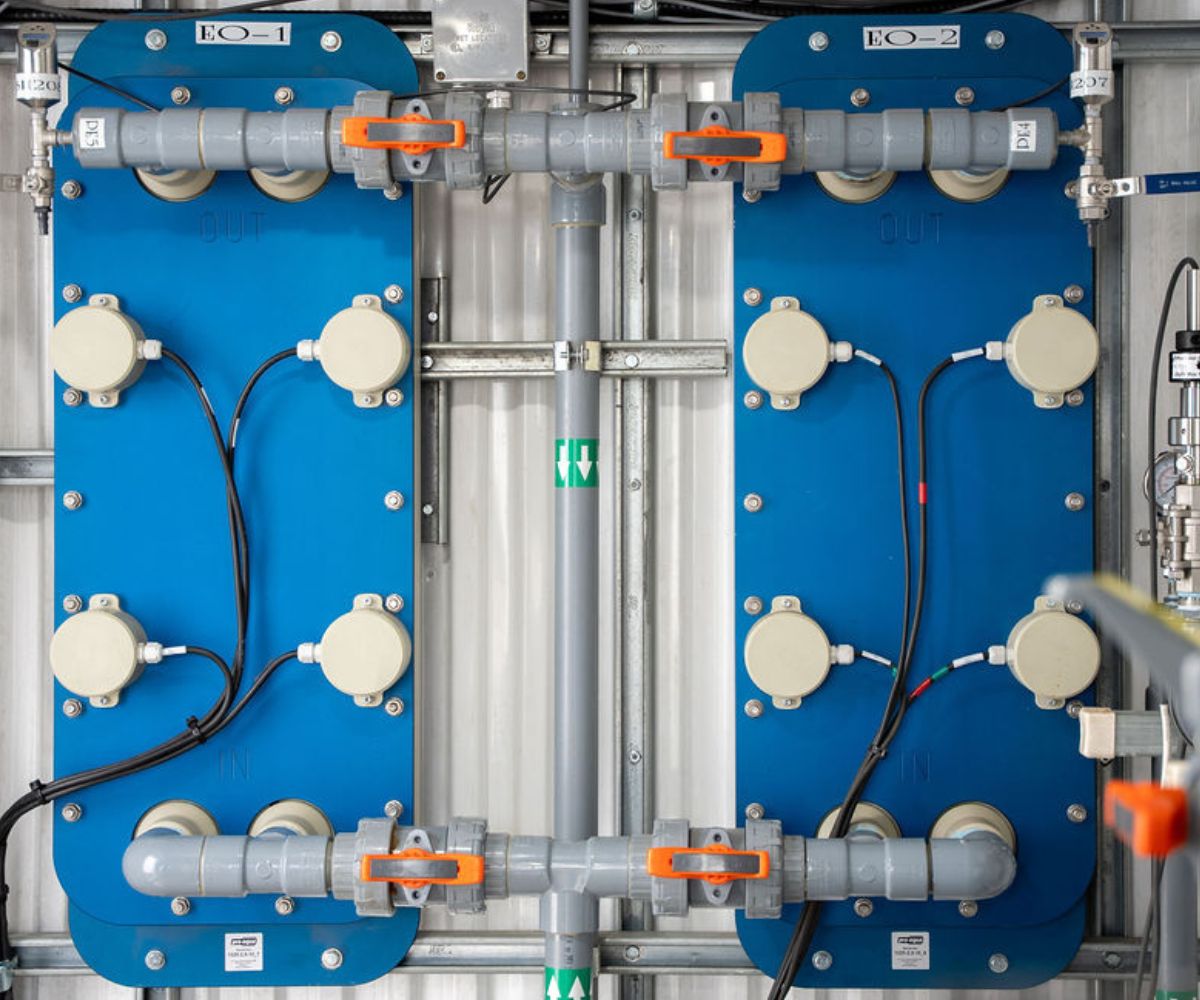

The PFASER destroys PFAS on-site using patented BDD electrodes and patent-pending perchlorate process. No sludge produced.

Yes. PFASER treats other recalcitrant contaminants such as ethanol, methanol, acetone, formaldehyde, phenol, ammoniacal nitrogen, to name but a few. It is very powerful at treating many contaminants simultaneously.

While electro-oxidation is effective for many PFAS compounds, its efficiency can vary depending on the specific PFAS type and water matrix. Ongoing research aims to optimize this technology for broader applications, such as sludge and soils. Long chain PFAS, precursors and some short chain PFAS are destroyed.

Absolutely. From small sites to large industrial hubs, PFASER module scales with your needs.

Lower than you think. It has a higher capital cost compared to conventional technologies or off-site disposal methods, but a lower operating cost and minimal maintenance. Thus, big savings over time compared to off-side disposal or conventional treatment.

Several technologies are being developed and implemented to destroy PFAS in water, including:

- Electro-Oxidation or Electrochemical Oxidation (EO) (the terms are synonymous): Uses electrical currents to break down PFAS molecules.

- Supercritical Water Oxidation (SCWO): Employs high-temperature and high-pressure water to oxidize PFAS.

- Plasma Treatment: Utilizes ionized gas to degrade PFAS compounds.

- Hydrothermal alkaline treatment (HALT): Uses high-temperature water with alkaline conditions to degrade contaminants like PFAS.

- Incineration: Involves burning PFAS at high temperatures to break down and destroy the chemical compounds.